5 Tips you need to know about the exhaust clamps

- Frank Fu

- November 18, 2022

- 3:13 am

- No Comments

How much do you know about the exhaust clamps? Today we are going to talk about the exhaust clamps in the following passage. We will mainly discuss some tips about choosing the exhaust clamps and the types of the exhaust clamps.

Tips:

- material:

The main materials of these clamps are aluminum, galvanized and stainless steel. The aluminum may easily get rust, so the stainless steel performs better. And when you want to buy the exhaust clamps, you’d better take the stainless steel exhaust clamps a priority.

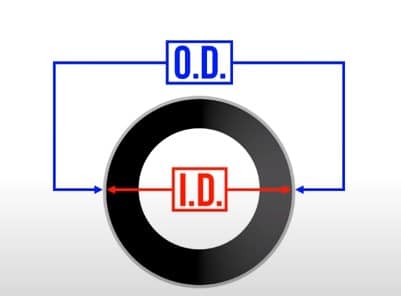

- OD&ID

There are different kinds of exhaust clamp sizes, like 2.25 inch, 2.5inch, 3 inch, 4 inch and so on. What we should know is about OD and ID. OD means the outer diameter, and ID means inner diameter.

Just as shown in the picture, the outer dimension(OD) is 3.2 inch and the inner dimension (ID)is 3 inch. And for the clamps and pipes, we all use its OD. For muffler, we all use their ID. So when you see a three-inch muffler and a three-inch exhaust pipe advertised this will mean that the pipe will slide into the muffler openings, and it’s called lap joint. The lap joint is probably the easiest connection to deal with because it can be secured using a saddle clamp or the proper band clamp. So when you buy the clamps, what you need to figure out is the OD and ID, and make sure you buy the right size. Or you will waste your money and get a wrong item.

- Some products that can use the clamps to connect

Exhaust piping, mufflers, collector reducers can all be connected by the exhaust clamps.

- Situation about using the exhaust clamps(pros)

Many people may wonder exhaust clamps vs welding which is better. Welding are exhausting which may not make a satisfying result and maybe it will leak and it require skilled worker. Then how to connect two exhaust pipes without welding? An exhaust clamps is a better choice for those who are first-timers for its easy-to-handle feature. And it is much cheaper than welding which can be just done at home. So if you are a rookie or you want to save money or you can’t find a good place to weld, you can choose the exhaust clamps. It won’t let you down.

- Some disadvantages about the clamps(cons)

The clamps which are made of aluminum will get rust easily. They corrode more easily with high heat. And you may need to fasten the clamps after you install them. We recommend using galvanized or stainless steel for better heat resistance. So you’d better choose some high-quality stainless or galvanized steel clamps instead of those aluminum exhaust clamps.

Exhaust Clamp Types

- butt joint clamps

As we can see in the picture, the butt joint clamps are the same at both sides. So when the objects you are going to connect are the same in size, you can choose to use the butt joint clamps. When two objects butt up against one another, you can use the butt joint clamps. And when meeting the lap joint (as mentioned above), butt joint clamps will also work.

- Lap joint clamps

The lap joint clamps are different in two sides. One side is bigger than the other side, so if the two objects need to be linked is in different sizes, you may need these kinds to connect them. When the fixture is fixed, the unique reaction block produces a complete “inner ring seal.” The I-Block is used to clamp the position of the bolts, helping to create a better 360° seal and helping to prevent exhaust and noise leakage

- Tri clamps

The phrase ‘Tri-Clamp’ was originally used to describe clamps comprised of three segments which are mainly rubber ring, exhaust clamp and a long snail. Tri-Clamp fittings are connections for pieces of pipe, which facilitate easy disassembly and cleaning.

- V band clamps

People call it V band because of the v shape right inside and has an outer band that holds everything together so basically it’s two machined inner pieces that weld in the exhaust system so you’d have a piece of exhaust tubing welded to this side and then one to the other side and they would join up here there’s a machined lip mail on this side, female flange on the other side, match them and then they’re held together on the outside with this clamp. It has a t-bolt across the top and a locking nut and because the tolerances are so tight in the machined lip here. It’s leak-free. It’s the best sealing exhaust clamps. Some people think that they are the best clamps for welding.